EDLab performs researches on vibration energy harvester (including piezoelectric and electromagnetic) with consideration of realistic loading (e.g. tire impact loading, bimodal vibration, various kinetic energy from engineering structures and human).

Vibration energy harvesting (EH) has grabbed attention as an autonomous and sustainable power solution for wireless sensor network. We study various vibration energy harvesting devices applicable to energy system monitoring (wind turbine), aerospace, railroad, human body, smart farm.

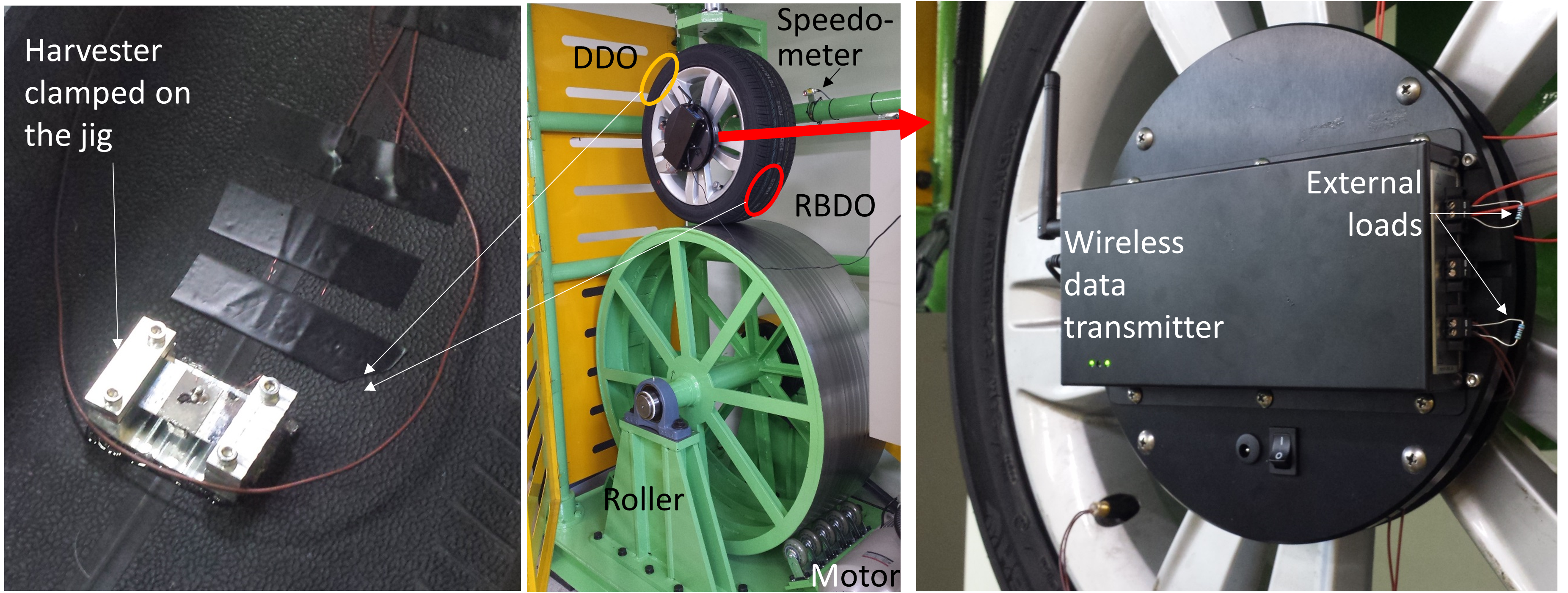

We study energy harvesters that overcome the weakness of linear harvesters and account for the arbitrary nature of vibration. For practical purposes, a broadband frequency vibration input is used to optimize the energy harvester design. Design variables are assigned and optimized in order to create optimal design of the energy harvester, which maximizes power output. We actively research on system integration on energy sustainable sensor node by combining energy harvester, power management circuit, storage unit, sensor, and wireless transmitter.

Related recent papers:

|

Broadband Energy Harvester for Varied Tram Vibration Frequency Using a 2-DOF Mass–Spring–Damper System

Smart Structures and Systems, 2023

This study presents a broadband vibrational energy harvester based on a |

|

A Pendulum-Based Frequency-Up Conversion Mechanism for Vibrational Energy Harvesting in Low-Speed Rotary Structures

Journal of Intelligent Material Systems and Structures, 2024

This paper proposes a pendulum-based frequency up-conversion mechanism for |

|

Smart Flexible 3D Sensor for Monitoring Orthodontic Forces: Prototype Design and Proof-of-Principle Experiment

Bioengineering, 2022

This paper presents the design and experimental validation of a smart, |

|

Nonlinear Dynamics of a Rotary Energy Harvester with a Double Frequency Up-Conversion Mechanism

Journal of Computational and Nonlinear Dynamics, 2020

This paper investigates the nonlinear dynamic behavior of a rotary |

S. Nezami, S. Lee, J. Jin, and K. W. Kang “Shape optimization of railroad vibration energy harvester for structural robustness and power generation performance,” Eng. Struct., Vol. 173, No. 15, pp. 460-471, 2018 ![]()

N. Chen, T. Wei, D. Ha, H. Jung, and S. Lee, “Alternating Resistive Impedance Matching for an Impact-Type Micro Wind Piezoelectric Energy Harvester,” IEEE T. Ind. Electron., Vol. 65, No. 9, pp. 7374-7382, 2018 ![]()

A. T. Eshghi, S. Lee, M. K. Sadoughi, C. Hu, Y. C. Kim, and J. H. Seo, “Design optimization under uncertainty and speed variability for a piezoelectric energy harvester powering a tire pressure monitoring sensor,” Smart Mater. Struct., Vol. 26, No. 10, 105037, 2017 ![]()