Topology/shape optimization is an important problem in most engineering systems for lightweight, performance enhancement, and cost reduction. EDLab is conducting researches on topology/shape optimization on structural system (e.g. civil structures, aircraft), multiphysical system (e.g. energy harvesting devices).

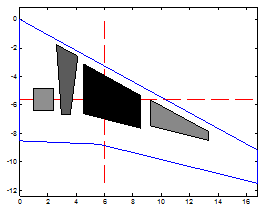

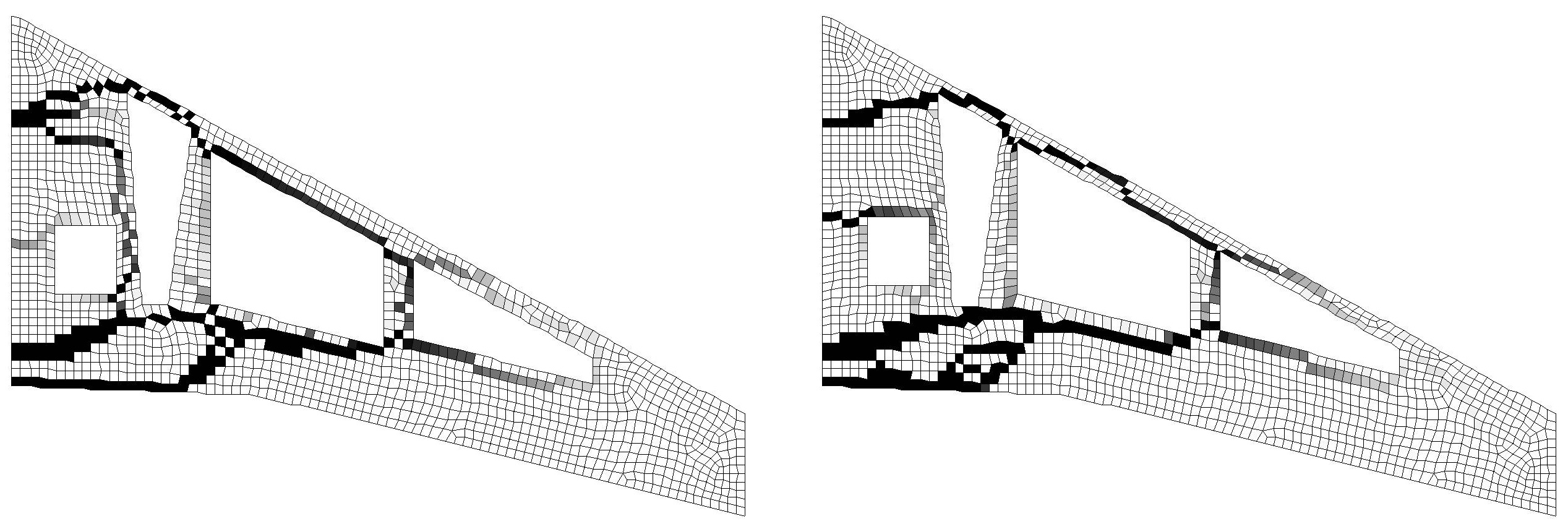

Aircraft wing system design: This research aims at founding a design framework for aircraft subsystem layout using design optimization methodologies. An aircraft system is very complex with its various subsystems: control system (flight control, engine control), fuel system, hydraulic system, and structural system. An advanced systematic design approach is needed for effective packaging of multiple subsystems while satisfying load-carrying performance and minimizing weight for energy efficiency. The proposed design framework provides multiple Pareto solutions by performing the consecutive two design steps: (i) subsystem allocation, and (ii) structural topology optimization

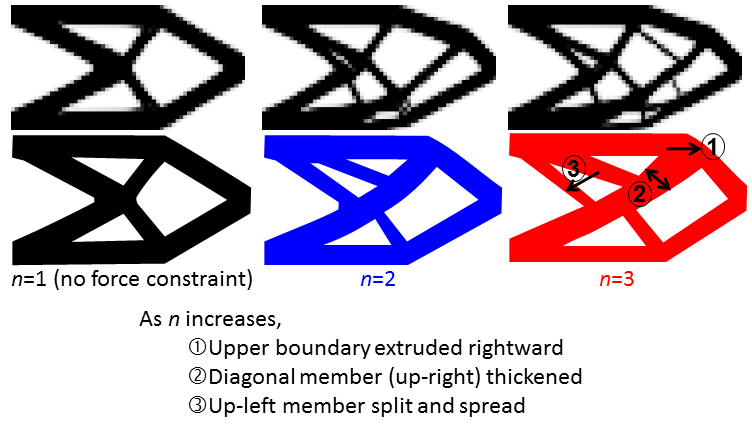

Load Path Design: Many failures in load-carrying structures occur due to error in calculating load path. For example, the certification failure in Boeing 787 assembly was caused by error in estimating load distribution between upper and lower fasteners of the center wingbox. It was also reported that two thirds of missed steady state and dynamic loads cases in Boeing for last 30 years were caused by inadequate load analysis. Even if the external limit loads and design loads are well defined, it is difficult to analyze/evaluate accurate internal loads that are applied various joints of complex systems, which can cause overload and early joint failure. Instead of trying to analyze internal load for a given joint configuration, the main objective of this paper is to design/control internal load path of load-carrying structures using a new topology optimization strategy. A new topology optimization formulation with a local control of interface load is formulated, to minimize the structural volume subject to constraints on the ratio of multiple internal interface loads (or joint loads).

|

|

| opological design change as the ratio of desired interface loads varies from 1 to 3 |

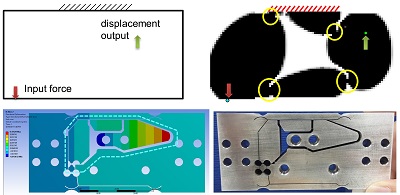

Null balance design: A well designed high precision module makes it possible to estimate the weight in a high resolution. Most of the formerly developed and patented module mechanisms use combination of lever systems to amplify the displacement output and reduce the output force. Former module designs are largely based on experience, and their design optimality has not been guaranteed in terms of kinematic synthesis in the design domain. In this research, we suggest topological formulations for the high precision null balancing module. Object function, constraints and the corresponding sensitivities are formulated for topology optimization. Topological optimal designs are post-processed and its realistic performance is verified.

|

|

Related recent papers:

M. Sung, S. Lee, and N. Kim, “Simultaneous Optimization of Printing Angle and Geometry for Additive Manufacturing using Topology Optimization,” Proceedings of the 12th World Congress on Structural and Multidisciplinary Optimization (WCSMO12), 5 – 9 June 2017, Braunschweig, Germany ![]()

M. Bakhtiarinejad, S. Lee, and J. Joo, “Topology Optimization based on Morphing Mesh for Simultaneous Component Relocation and Frame Structure Design,” Struct. Multidiscip. O., Volume 55, Issue 1, pp 297–315, 2017 ![]()

M. Bakhtiarinejad, J. Joo, and S. Lee, “A New Topology Optimization Method for Simultaneous Design of Component Layout and Frame Structure of Aircraft Wing,” AIAA Science and Technology Forum and Exposition (SciTech) 2016, San Diego, USA, Jan. 2016 ![]()